02 Commercial Ship & Fluiddynamics

Our services for commercial ship design and fluiddynamics.

Hull design

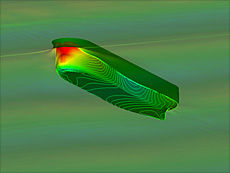

Hull Form Design Using Advanced CFD

ACT provides hull form design and development services for commercial ships, delivering superior hydrodynamic performance, low resistance, and high propulsion efficiency, while fully satisfying operational and design constraints.

We have one of the longest histories in CFD-based ship hull design, having started the application of CFD to hull form development in 1993.

Through decades of practical use, we have accumulated extensive know-how, validated methodologies, and proven results.

By applying CFD at the early design stage, we can efficiently evaluate a wide range of hull form candidates prior to model tank testing, significantly reducing both development time and cost while improving final performance.

Track Record in Commercial Ship Design

Since 2006, we have been providing advanced hull form design services to shipbuilding yards and shipping companies worldwide.

Across all projects, we have consistently achieved 3–15% reductions in Brake Horsepower (BHP) compared with existing vessels of similar type.

For typical bulk carriers with daily fuel consumption of approximately 20–50 tons/day, even a 5% BHP reduction translates into fuel savings of 1–2.5 tons per day, delivering significant operational cost and emissions reductions throughout the vessel’s service life.

Selected Design Experience

Autonomous and Advanced Vessels

-

Autonomous Surface Vessels (ASVs)

Since 2019, we have been engaged in hull form development for ASVs.

High-Speed and Specialized Craft

-

Hydrofoil Catamarans (foil system & hull design) for Setouchi Craft

-

32m type: launched in 2025, commercial service on the Hiroshima–Matsuyama route

-

28m type: launched in 2023, currently in commercial service (Hiroshima–Etajima)

-

37m type: launched in 2021, in commercial service on the Naha–Zamami route (Okinawa)

-

30m type: launched in 2017, in commercial service in Nagasaki

-

-

Crew Transfer Vessel (CTV) hull design

Commercial Ships

-

Bulk Carriers

Hull designs for more than 30 vessels, ranging from Handy size to Cape size. -

Container Ships

Hull designs for over 20 vessels, from 1,000 TEU to 9,300 TEU class.

Consultancy on fluiddynamics

ACT offers a wide range of consultancy services to support the client for the optimum solution to various kinds of fluiddynamic problems. CFD is one of the strong tools to analyze the flow of a fluiddynamic problem and we have various experience and know-hows to adopt CFD to each problem effectively.

Our achievements for the range of consultancy services include the following;

The wing sail design and performance prediction by CFD and EPP(Energy Prediction Program) for the Wind Challenger project since 2009 as a start-up member. It has been clarified that the averaged BHP reduction is over 20% and if the wind speed is 20kts and the direction is from 90deg to the hull the reduction attains about 50%.

In the subsequent project, the Wind Hunter project, the design of the sail arrangement and the catamaran hull form were carried out as part of a joint research with MOL.

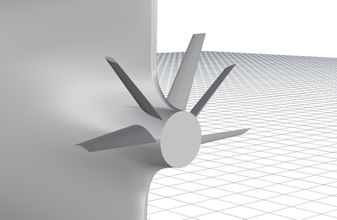

Developments of various new devices to reduce the BHP by improving the propulsion efficiency in the stern region. The stator fins installed on the propeller boss of a bulk carrier reduce the BHP by about 5%.

Analysis of the wind pressure drag on the superstructure of a container and PCC ship and development of a new shape to reduce the drag by more than 20%.

Unsteady CFD analysis to clarify the mechanism of the SRD device developed by SHIMANO INC. for the rowing boat foot stretcher.

Software development & consultancy

ACT has developed various kinds of software to improve design work efficiency. Some of the software has been provided to clients for their design work. We also support the system integration for the design-by-CFD by developing and customizing design software and providing necessary training for effective usage.

Our served software includes the following;

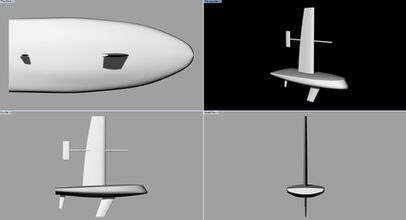

HullDes/AutoDes – An Innovative Hull Design Support Program

HullDes/AutoDes is an innovative hull design support program jointly developed by ACT and NMRI.

While conventional design processes required enormous manual work and countless trial-and-error steps, AutoDes enables a fully automated workflow from hull form modification to CFD analysis and optimization. Designers can now achieve hull development with unprecedented speed and accuracy.

One of its most remarkable features is the optimization capability incorporating a proprietary discrete SQP method. By manipulating parametric variables or distribution functions within specified regions, hull forms can be flexibly deformed. In combination with CFD, the system automatically performs iterative calculations and optimizations, ultimately leading to the most efficient hull design.

Key Features

Flexible Data Input/Output

-

Import/export multiple NURBS hull surfaces in srf (FastShip) or IGES format

-

Conversion from IGES to NAPA format

Advanced Hull Form Modification

-

Freely modify key parameters such as Cp, LCB, frame lines, and local geometry

-

Box-type deformation within designated regions

Automated Mesh Generation

-

Automatic generation of O-H/O-O type structured meshes for CFD

-

Surface clustering and special transom treatments

-

High-speed parallel processing with OpenMP

-

Overset grid generation including rudders, fins, ducts, and appendages

Analysis & Optimization

-

Seamless CFD integration with NMRI’s Neptune, Surf, and Nagisa

-

Automatic hull deformation and optimization using the proprietary SQP method

Fully Automated Workflow

-

From hull form modification → CFD analysis → optimization, the entire multi-step process is automated

Proven Performance

HullDes/AutoDes has already been adopted by over 20 shipyards and consulting firms, delivering tangible results in real-world projects.

It represents a new era of design support tools, combining the intuition and experience of designers with scientifically grounded optimization to deliver superior hull solutions.

For further details, please contact NMRI.

CFD and FEM interaction system

Waterbag deformation prediction software can simulate the towed waterbag deformation due to static and dynamic water pressure. The CFD and FEM iteration technique is used.

SpinFlow software can simulate the flow around a spinnaker and a main sail on a sailing yacht. The flying sails should deform according to the air pressure. The dynamic deformation of the sails can be achieved by FEM as a function of the SpinFlow. The iterative work between the CFD and the FEM can be automatically carried out until the deformation has converged. The GUI is provided for the pre and post processes in which the mesh is automatically created. The results are also visualized in the post process functions.

ParaFlow software can simulate the flow around a parachute to evaluate the fluid dynamic forces acting on the surface. The system is very similar to the above SpinFlow. The boundary conditions for the ventilation and the permeable areas can be set easily on the view window of the GUI.